Description

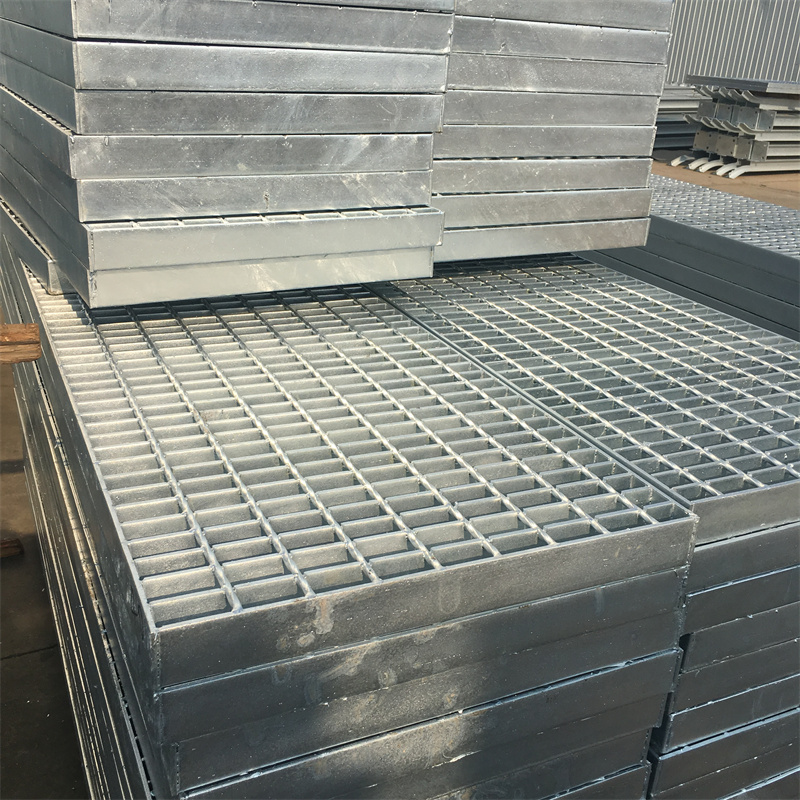

Heavy duty steel grating supplies far greater strength-to-weight ratio than other flooring materials to bear the heavy load such as forklift or truck traffic. Because these gratings are typically in more severe service, it is highly recommended that all open ends be trim or load banded. The welded band bar helps distribute these loads and minimizes potential panel distortion.The Characteristics Of Heavy Type Steel Plate Grating

The biggest characteristic of heavy steel plate is that it has a large load capacity and the strongest impact resistance. It is recommended to use toothed steel lattice plate, which can provide better friction. It is the preferred product for places with large loads and many vehicles. Pressing lock is the best manufacturing method, which can effectively prevent the tilt instability of bearing flat steel. Avoid load flat steel deformation.Heavy Type Steel Lattice Plate Grating Requirements

The production technology of heavy steel plate has special requirements. Generally, high quality carbon structural steel or stainless steel is required to have high strength and good corrosion resistance. Its chemical composition and mechanical properties shall comply with the requirements of Q235A of GB70088 or 0Crl8Ni9 of GBl22092, respectively. Each bearing flat steel and rimmed flat steel are double breaded fillet welding and the weld is not less than 3MM; The joint of each bearing flat steel and twist rod is fully welded; After the production of semi-finished black parts, the spatter, welding slag and burr must be removed, the corners without sharp edges must be polished, and the whole plate must be flat. The heavy steel plate is also very strict for galvanizing. When the thickness of bearing flat steel is not less than 5MM, the average weight of zinc layer after galvanizing shall not be less than 610g/㎡; When the thickness of the bearing flat steel is less than 5mm, the average weight of zinc layer after galvanizing shall not be less than 460g/㎡. The quality and requirements after galvanizing should conform to the latest "hot dip Galvanizing" GB/T13912-2008 standard. Heavy Type Steel Grating| Type | bearing bar Width | bearing bar thickness | Cross barsize | Theory weight | Loadand deflection | Clear span | ||||||||||||||

| 200 | 400 | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | 2600 | 2800 | 3000 | ||||||

| G1508/40/100 | 150 | 8 | 8×8 | 284.9 | U | 25500 | 6375 | 2833 | 1593 | 1020 | 708 | 520 | 398 | 314 | 255 | 210 | 177 | 150 | 130 | 113 |

| D | 0.05 | 0.18 | 0.41 | 0.73 | 1.15 | 1.66 | 2.26 | 2.95 | 3.74 | 4.63 | 5.6 | 6.7 | 7.85 | 9.17 | 10.54 | |||||

| G1308/40/100 | 130 | 8 | 8×8 | 247.6 | U | 19153 | 4788 | 2128 | 1197 | 766 | 532 | 390 | 299 | 236 | 191 | 158 | 133 | 113 | 97 | 85 |

| D | 0.05 | 0.21 | 0.48 | 0.85 | 1.33 | 1.91 | 2.6 | 3.14 | 4.32 | 5.34 | 6.49 | 7.76 | 9.11 | 10.55 | 12.22 | |||||

| G1208/40/100 | 120 | 8 | 8×8 | 229.0 | U | 16320 | 4080 | 1813 | 1020 | 653 | 453 | 333 | 255 | 201 | 163 | 134 | 113 | 96 | 83 | 72 |

| D | 0.06 | 0.23 | 0.52 | 0.92 | 1.44 | 2.07 | 2.83 | 3.7 | 4.68 | 5.8 | 7 | 8.39 | 9.85 | 11.5 | 13.2 | |||||

| G1008/40/100 | 100 | 8 | 8×8 | 191.7 | U | 11333 | 2833 | 1259 | 708 | 453 | 314 | 231 | 177 | 139 | 113 | 93 | 78 | 67 | 57 | 50 |

| D | 0.07 | 0.28 | 0.62 | 1.1 | 1.73 | 2.48 | 3.39 | 4.45 | 5.61 | 6.97 | 8.43 | 10.05 | 11.94 | 13.73 | 15.94 | |||||

| G908/40/100 | 90 | 8 | 8×8 | 173.1 | U | 9180 | 2295 | 1020 | 573 | 367 | 255 | 187 | 143 | 113 | 91 | 75 | 63 | 54 | 46 | 40 |

| D | 0.08 | 0.31 | 0.69 | 1.22 | 1.92 | 2.77 | 3.77 | 4.93 | 6.26 | 7.72 | 9.35 | 11.17 | 13.24 | 15.25 | 17.57 | |||||

| G808/40/100 | 80 | 8 | 8×8 | 154.4 | U | 7253 | 1813 | 805 | 453 | 290 | 201 | 148 | 113 | 89 | 72 | 59 | 50 | 42 | 37 | 32 |

| D | 0.09 | 0.34 | 0.77 | 1.38 | 2.16 | 3.11 | 4.25 | 5.56 | 7.04 | 8.71 | 10.5 | 12.66 | 14.73 | 17.53 | 20.11 | |||||

| G758/40/100 | 75 | 8 | 8×8 | 145.1 | U | 6375 | 1593 | 708 | 398 | 255 | 177 | 130 | 99 | 78 | 63 | 52 | 44 | 37 | 32 | 28 |

| D | 0.09 | 0.37 | 0.83 | 1.47 | 2.31 | 3.33 | 4.54 | 5.92 | 7.5 | 9.27 | 11.25 | 13.55 | 15.78 | 18.47 | 21.42 | |||||

| G756/30/100 | 75 | 6 | 8×8 | 140.1 | U | 6375 | 1593 | 708 | 398 | 255 | 177 | 130 | 99 | 78 | 63 | 52 | 44 | 37 | 32 | 28 |

| D | 0.09 | 0.37 | 0.83 | 1.47 | 2.3 | 3.33 | 4.54 | 5.91 | 7.49 | 9.26 | 11.24 | 13.53 | 15.76 | 18.44 | 21.39 | |||||

| G756/40/100 | 75 | 6 | 8×8 | 110.1 | U | 4781 | 1195 | 531 | 298 | 191 | 132 | 97 | 74 | 59 | 47 | 39 | 33 | 28 | 24 | 21 |

| D | 0.09 | 0.37 | 0.83 | 1.47 | 2.3 | 3.31 | 4.52 | 5.9 | 7.56 | 9.22 | 11.25 | 13.55 | 15.93 | 18.48 | 21.44 | |||||

| G706/30/100 | 70 | 6 | 8×8 | 131.1 | U | 5553 | 1388 | 617 | 347 | 222 | 154 | 113 | 86 | 68 | 55 | 45 | 38 | 32 | 28 | 24 |

| D | 0.1 | 0.39 | 0.89 | 1.58 | 2.47 | 3.56 | 4.85 | 6.32 | 8.04 | 9.96 | 11.99 | 14.41 | 16.82 | 19.9 | 22.65 | |||||

| G706/40/100 | 70 | 6 | 8×8 | 103.2 | U | 4165 | 1041 | 462 | 260 | 166 | 115 | 85 | 65 | 51 | 41 | 34 | 28 | 24 | 21 | 18 |

| D | 0.1 | 0.39 | 0.88 | 1.58 | 2.46 | 3.55 | 4.87 | 6.38 | 8.05 | 9.91 | 12.09 | 14.19 | 16.85 | 19.95 | 22.7 | |||||